Hot Melt Powder Coaters

(3 Reviews)

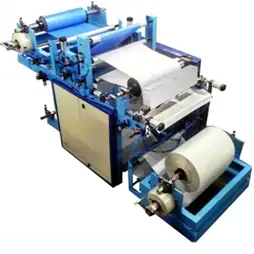

- Hot Melt Coating Machine for Sticker Paper Gumming

Description

Specification

Hot Melt Coating Machine is suitable for producing adhesive sticker, label paper, medical tapes, double-side adhesive tapes, cloth tapes, double-side foam adhesive tape, clean adhesive tape, craft paper tape, Aluminium foil tapes, fabric tapes, shoes materials and etc. of 510mm width & 600mm dia. with 15 gsm to 40 gsm hot melt coating.

Process 1. Silicon paper of 510mm will be coated with hot melt. 2. Lamination (transfer of HM on Face Paper) of face paper in roll form. 3. Winding of Si paper & Face paper in roll. Machine Type: Die coating Max. Size of coating: 510mm, GSM: 15 to 55 Max. Speed of coating: Speed 50 mpm at M/c specifications: 1. Unwind 1: To hold 510 mm width material.; 1000 mm Dia. Max. Air Shaft to suit 3” paper core. ;Magnetic Brake with load Cell tension control ; Servo Motor Web aligner with ultra sonic sensor. 2. Coating Station: Slot Die coating.; Accurate Temp. Control.; All silicon rolls dynamic balanced.; Back up roller Pneumatic operated. 3. Unwind 2: To hold 510 mm width material.; 1000 mm Dia. Max. Air Shaft to suit 3” paper core. ;Magnetic Brake with load Cell tension control ; Servo Motor Web aligner with ultra sonic sensor. 4. Lamination Nip: Dynamic balanced Metal roll & Silicone roll, Operation & pressure Pneumatic, Clutch Drive to the nip 5. Rewind : Centre winding system, To hold 510mm width material.; 600 mm Dia. Max.; 76 MM core ID.; Tapper tension controlled winding with load cell feedback and Magnetic clutch, AC Drive for controlled winding. 6. Permelter: Tank capacity 60 Kgs., Melting Capacity 30 Kgs/hr, Pump Capacity 0.5 Lit/Min, Accurate Temp. Control., Filters and pressure sensor, Accurate flow control 7. Hot melt Hose: To Supply 0.5 Kgs/min., Length 3 m, Accurate Temp. Control. 8. DIMENTIONS: 7 m X 3 m X 2 m 9. Total Electrical Load : 30 KW

Process 1. Silicon paper of 510mm will be coated with hot melt. 2. Lamination (transfer of HM on Face Paper) of face paper in roll form. 3. Winding of Si paper & Face paper in roll. Machine Type: Die coating Max. Size of coating: 510mm, GSM: 15 to 55 Max. Speed of coating: Speed 50 mpm at M/c specifications: 1. Unwind 1: To hold 510 mm width material.; 1000 mm Dia. Max. Air Shaft to suit 3” paper core. ;Magnetic Brake with load Cell tension control ; Servo Motor Web aligner with ultra sonic sensor. 2. Coating Station: Slot Die coating.; Accurate Temp. Control.; All silicon rolls dynamic balanced.; Back up roller Pneumatic operated. 3. Unwind 2: To hold 510 mm width material.; 1000 mm Dia. Max. Air Shaft to suit 3” paper core. ;Magnetic Brake with load Cell tension control ; Servo Motor Web aligner with ultra sonic sensor. 4. Lamination Nip: Dynamic balanced Metal roll & Silicone roll, Operation & pressure Pneumatic, Clutch Drive to the nip 5. Rewind : Centre winding system, To hold 510mm width material.; 600 mm Dia. Max.; 76 MM core ID.; Tapper tension controlled winding with load cell feedback and Magnetic clutch, AC Drive for controlled winding. 6. Permelter: Tank capacity 60 Kgs., Melting Capacity 30 Kgs/hr, Pump Capacity 0.5 Lit/Min, Accurate Temp. Control., Filters and pressure sensor, Accurate flow control 7. Hot melt Hose: To Supply 0.5 Kgs/min., Length 3 m, Accurate Temp. Control. 8. DIMENTIONS: 7 m X 3 m X 2 m 9. Total Electrical Load : 30 KW